- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Aluminum Nitride Heaters

Semicorex Aluminum Nitride Heaters are high-performance ceramic heating elements known for their exceptional thermal conductivity, rapid response, and electrical insulation. Choosing Semicorex means partnering with a trusted expert in advanced ceramic technologies—delivering precision-engineered solutions, consistent quality, and responsive technical support tailored to your application needs.*

Send Inquiry

Semicorex Aluminum Nitride Heaters are state-of-the-art ceramic heating elements designed for applications that demand high thermal conductivity, electrical insulation, and exceptional durability. Engineered from aluminum nitride ceramic, these heaters provide rapid and uniform heating, making them ideal for high-precision environments such as semiconductor processing, medical diagnostics, and advanced analytical instrumentation.

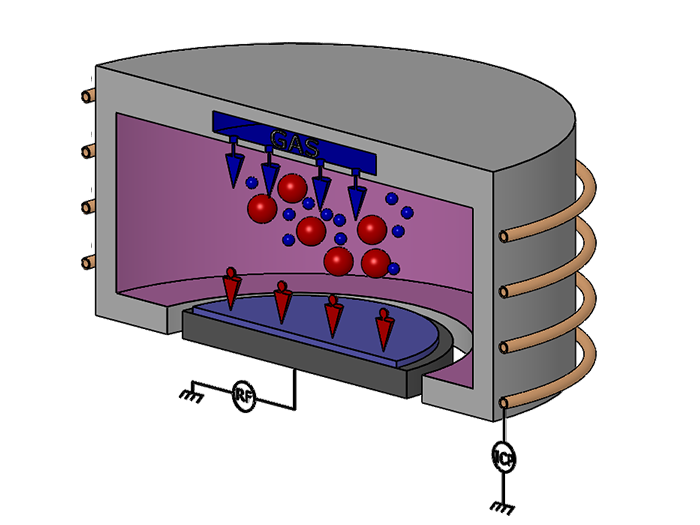

Aluminum Nitride Heaters are key components in semiconductor thin film deposition equipment. They are directly applied to the process chamber and in direct contact with the wafer. They not only carry the wafer, but also ensure that the wafer obtains a

stable and uniform process temperature. This feature is essential for high-precision reactions on the wafer surface and the generation of uniform thin films.

Typically, Aluminum Nitride Heaters includes a ceramic substrate with a wafer loading surface and a cylindrical support body that supports it on the back. In addition to a resistive heating circuit for heating, an RF electrode and an electrostatic chuck electrode and other conductors are also provided inside or on the surface of the ceramic substrate.

Thin film deposition equipment usually uses ceramic materials based on aluminum nitride (AlN) because it involves a high-temperature environment. The reason why Aluminum Nitride Heaters are favored in semiconductor manufacturing is mainly due to their unique physical and chemical properties. Aluminum nitride not only has high thermal conductivity and can achieve rapid heating and cooling in a short time, but also has good electrical insulation and mechanical strength, ensuring the stability and reliability of the heater. In addition, the thermal expansion coefficient of aluminum nitride is similar to that of silicon, which helps to reduce the impact of thermal stress on the wafer and improve the process yield.

Generally speaking, ceramic heaters are mainly used in thin film deposition equipment. Since it involves high-temperature processes, the ceramic material used is mainly aluminum nitride; electrostatic chucks are mainly used in etching equipment, and the ceramic material used is mainly aluminum oxide. With the development of semiconductor technology, there is an overlap between ceramic heaters and electrostatic chucks. For example, ceramic heaters used in thin film deposition equipment are equipped with electrostatic chucks, which have the dual functions of high-temperature heating and electrostatic adsorption. Electrostatic chucks used in etching equipment also begin to involve high-temperature processes, and the ceramic material must be changed from aluminum oxide to aluminum nitride.