- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Alumina Wafer Polishing Carrier

Semicorex Alumina Wafer Polishing Carrier's application across various industries, from semiconductors to photovoltaics, playing a crucial role in the grinding and chemical mechanical polishing (CMP) processes of wafers.

Send Inquiry

Material Characteristics of Semicorex Alumina Wafer Polishing Carrier

Composition and Manufacturing Process

Semicorex Alumina Wafer Polishing Carrier is meticulously crafted from high-purity ultra-fine alumina powder, with a purity level of 99.7% or higher. This material is molded and then fired in a high-temperature environment to achieve its final form. The use of such high-purity alumina ensures that the carrier possesses exceptional mechanical and chemical properties, making it ideal for demanding industrial applications. The firing process enhances the material’s density and structural integrity, contributing to its durability and performance.

Mechanical and Chemical Properties

The Alumina Wafer Polishing Carrier is characterized by its high mechanical strength, which allows it to withstand significant stress and pressure during the polishing process. Its high wear resistance ensures longevity, even under continuous use in abrasive environments. Additionally, the carrier exhibits excellent electrical insulation properties, making it suitable for applications where electrical interference must be minimized. Its high chemical stability and good heat resistance enable it to perform effectively in environments exposed to corrosive substances and elevated temperatures.

Advantages in Wafer Processing

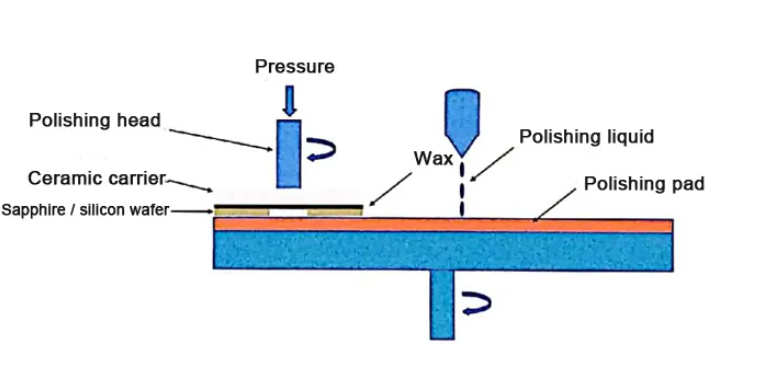

In the realm of semiconductor manufacturing, the use of ceramic grinding discs, such as the Alumina Wafer Polishing Carrier, represents the most advanced and efficient method for grinding silicon wafers. By employing ceramic plates instead of traditional cast iron plates, the risk of surface damage or contamination on the wafer is significantly reduced. This approach minimizes the introduction of metal ions, which can adversely affect the wafer’s quality. Consequently, the subsequent processing of silicon is streamlined, reducing the time required for corrosion processes and enhancing production efficiency. This not only improves the utilization of silicon but also reduces material loss, leading to cost savings and increased output.

Applications of Semicorex Alumina Wafer Polishing Carrier

![]() Semiconductor Industry

Semiconductor Industry

The Alumina Wafer Polishing Carrier is extensively used in the semiconductor industry, where it plays a crucial role in the grinding and chemical mechanical polishing (CMP) processes of wafers. Its high purity and mechanical properties ensure that semiconductor devices are manufactured with precision and minimal defects, contributing to the overall quality and performance of electronic components.

Petroleum and Chemical Industries

In the petroleum and chemical sectors, the Alumina Wafer Polishing Carrier is utilized for its chemical stability and resistance to corrosive environments. It serves as a reliable component in various mechanical and electronic parts, where durability and resistance to harsh chemicals are paramount.

Photovoltaic and Liquid Crystal Industries

The photovoltaic and liquid crystal industries benefit from the use of Alumina Wafer Polishing Carriers in the manufacturing of solar panels and display technologies. The carrier’s ability to maintain structural integrity and resist wear ensures that these products are produced with high efficiency and minimal waste, enhancing the overall sustainability and cost-effectiveness of production processes.

Additional Industrial Applications

Beyond these primary industries, the Alumina Wafer Polishing Carrier finds applications in microwave induction disks, insulation materials, vacuum equipment, and other mechanical and electronic parts. Its versatility and robust performance make it an indispensable component in a wide array of industrial applications, where precision and reliability are critical.