- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

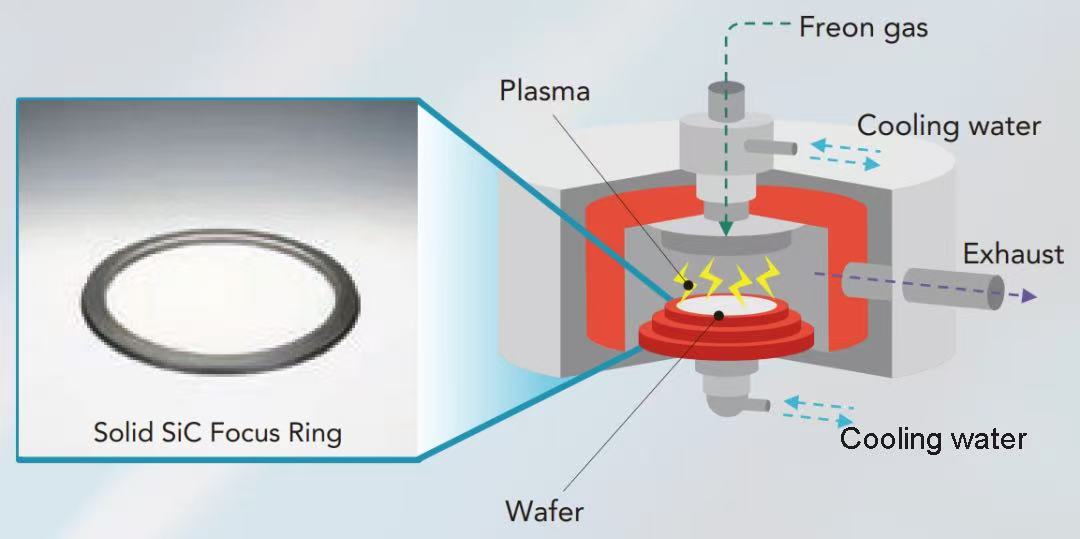

Silicon Carbide Focus Rings

Silicon carbide focus rings, the crucial ring parts, are specially designed to improve the uniformity and stability of wafer etching in the semiconductor plasma etching. They are renowned for their excellent performance in promoting uniform plasma distribution and optimizing electric field environment.

Send Inquiry

Silicon carbide focus rings are commonly installed in the reaction chamber of etching equipment, placed around the wafer support surface of the electrostatic chuck. This installation arrangement can successfully fill the height difference between the wafer edge and the electrode, focusing plasma in the reaction chamber onto the wafer surface to achieve uniform etching and also preventing the diffusion of plasma outward from the wafer edge to avoid the problem of over-etching the wafer edge.

High-quality etching components can provide a stable electric field environment for the etching process. Semicorex’s silicon carbide focus rings are manufactured from high-performance silicon carbide materials via chemical vapor deposition. Our focus rings are capable for adjusting the electric field distribution around the wafer, significantly reducing etching deviations or discharge phenomena caused by uneven electric fields.

Semiconductor wafers are easily susceptible to particulate contamination, so plasma etching processes must be carried out in ultra-clean ion etching reaction chambers. As the primary component of etching equipment, silicon carbide focus rings come into direct contact with the wafer edge in the actual operation, also required to meet ultra-high cleanliness standards. Semicorex's silicon carbide focus rings offer the advantages of high purity and low impurity content, which can precisely meet the stringent cleanliness requirements of semiconductor etching processes. This greatly contributes to reduce wafer defects and improves wafer production yield.

During plasma etching process, etching gases such as fluorine and oxygen are introduced into the reaction chamber. The etching equipment's chemical corrosion resistance is severely challenged by the long-term corrosion caused by process gases. With its superior resistance property to plasma corrosion, silicon carbide is the optimal material choice for focus ring manufacturing. By lowering the possibility of corrosion-related component damage and minimizing the need for frequent replacement and maintenance, silicon carbide focus rings can significantly increase the efficiency of semiconductor wafer manufacturing.