- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Quartz Crucible for Silicon Single Crystal Pulling

Semicorex Quartz Crucible for Silicon Single Crystal Pulling is made of high-quality fused quartz, the crucible has multiple layers, the inner layer is extremely high quality and dense to ensure the quality of single crystal. Semicorex is professional for the Quartz Crucible for Silicon Single Crystal Pulling products with extensive experience.*

Send Inquiry

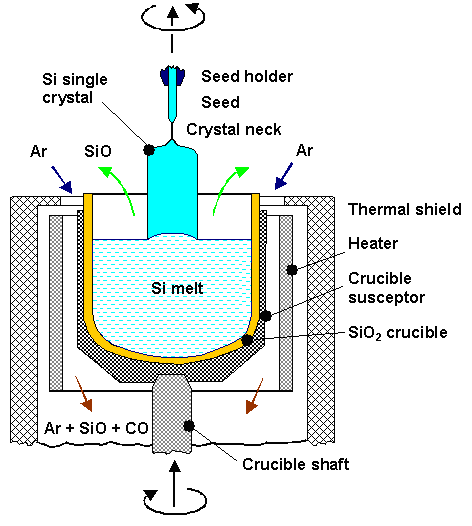

Semicorex Quartz Crucible for Silicon Single Crystal Pulling is the core component in Silicon wafer fabrication. The single-crystal preparation stage determines technical parameters, such as the diameter, crystal orientation, doping type, resistivity range and distribution, oxygen and carbon concentration, minority carrier lifetime, and lattice defects of the silicon. It requires that micro-defects, oxygen concentration, metal impurities, and carrier concentration uniformity all be controlled within a certain range.

In the Czochralski single-crystal growth process, the Quartz Crucible for Silicon Single Crystal Pulling needs to withstand temperatures higher than the melting point of silicon (1420℃). The quartz crucible is mostly translucent and composed of multiple layers.

The outer layer is a region with high bubble density, called the bubble composite layer; the inner layer is a 3-5mm transparent layer, called the bubble depletion layer. The presence of the bubble depletion layer reduces the density of the crucible-solution contact area, thereby improving single-crystal growth.

Since the inner layer of quartz crucible directly contacts with the Silicon liquid, it will be continuously dissolving into Silicon, and the micro bubble in the crucible transparent layer will grow up to crack and release the quartz particles and micro bubbles. These impurities then flow through the entire Silicon melt, directly affects the crystallization and quality of the silicon single crystal.

Quartz Crucible for Silicon Single Crystal Pulling directly contacts with Silicon liquid, so the impurities and bubbles which are not efficiently controlled in the production process, it will obviously affect the pulling crystal results, even lead to the fail to crystal pulling and material spoilage/waste. Because single-crystal silicon wafers require high purity and the cost of a single crystal pulling process is high, there are high demands on Quartz Crucible for Silicon Single Crystal Pulling in terms of purity, bubble performance, and quality stability.

Impurities: Impurities directly affect the performance and yield of single crystals. Therefore, the impurity content of the quartz crucible that is in direct contact with the silicon melt is crucial. Excessive impurities in the crucible often lead to crystallization in the quartz crucible (local accumulation of impurity ions leading to reduced viscosity). If crystallization occurs near the inner surface, an excessively thick local crystallization layer is prone to peeling off, preventing further single-crystal growth; if a thick crystallization layer forms on the outer wall, bulging at the bottom or curvature is likely to occur; if crystallization penetrates the crucible body, it can easily lead to a series of serious consequences such as silicon leakage.

Bubbles: High-purity quartz sand itself contains gas-liquid inclusions. During the crystal pulling process, the inner surface of the crucible in contact with the silicon melt continuously dissolves into the silicon melt. The micro bubbles in the transparent layer continuously grow, and the bubbles closest to the innermost surface rupture, releasing quartz micro particles and micro bubbles into the silicon melt. The impurities within these micro particles and micro bubbles are carried throughout the entire silicon melt, directly affecting the crystallization of silicon (yield rate, crystallization rate, heating time, direct processing costs, etc.) and the quality of the single-crystal silicon (perforated wafers, black chips, etc.).