- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

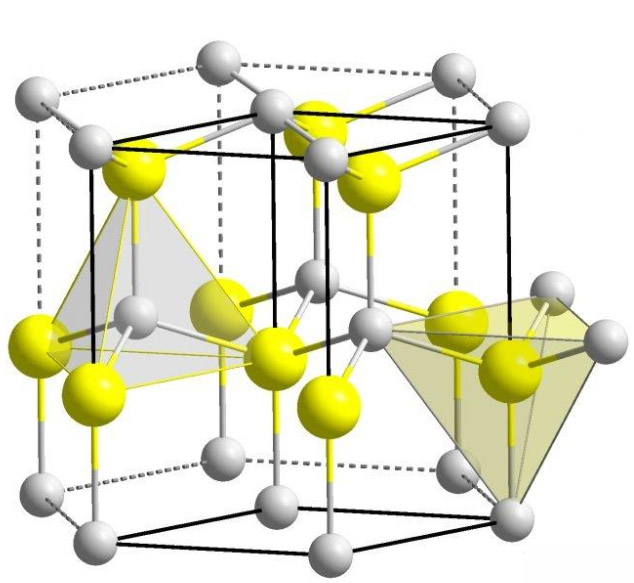

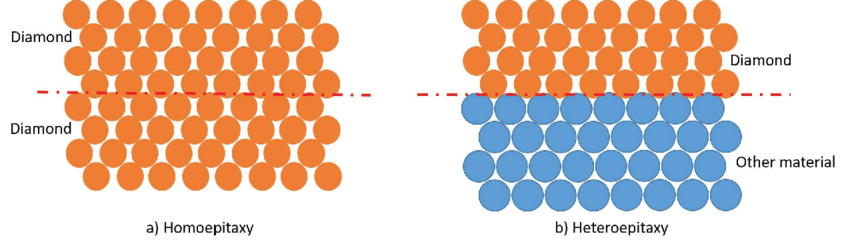

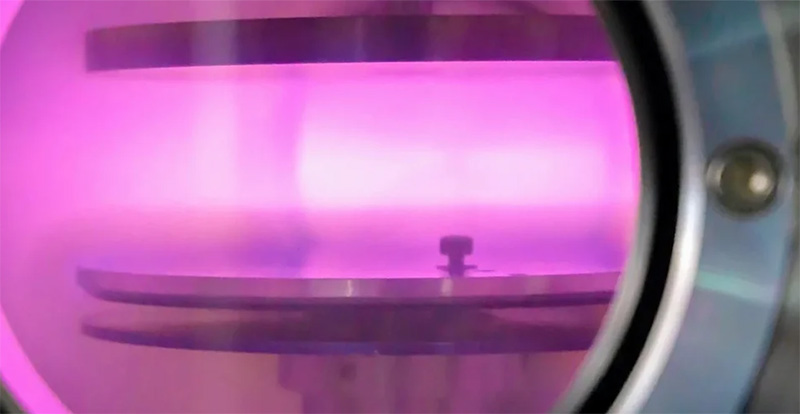

Homoepitaxy and Heteroepitaxy Explained Simply

Homoepitaxy and heteroepitaxy play pivotal roles in material science. Homoepitaxy involves the growth of a crystalline layer on a substrate of the same material, ensuring minimal defects due to perfect lattice matching. In contrast, heteroepitaxy grows a crystalline layer on a different material sub......

Read More