- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is the Air-floating Roller?

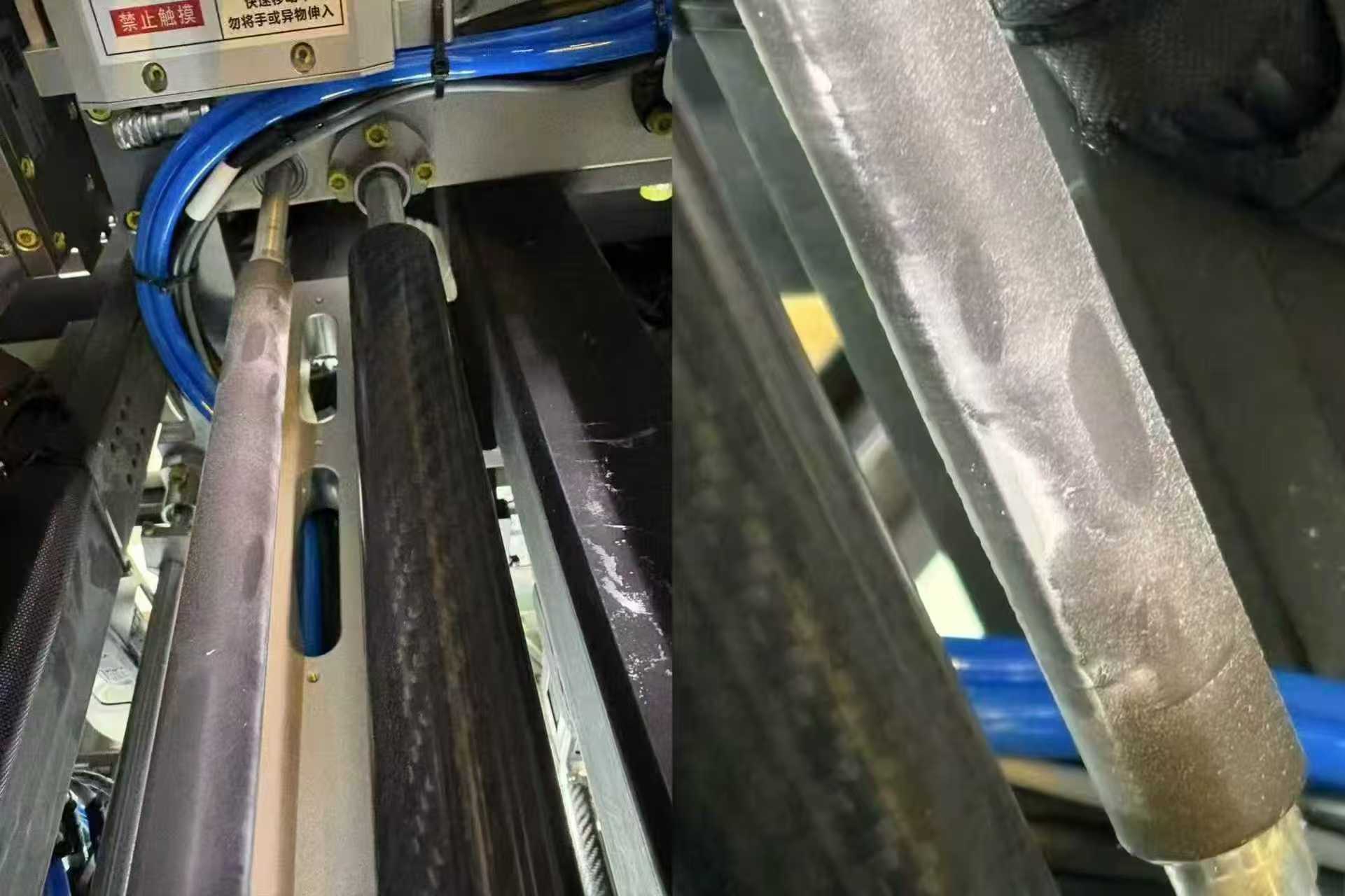

The air-floating roller is the high-precision component that can achieve contact-free support and smooth rotational guidance by forming a stable air film between the roller surface and the thin film materials' surface. Based on the principle of air lubrication, the air-floating rollers are able to generate nearly no friction or wear with the material during the manufacturing process. With their excellent performance, the air-floating rollers are widely applied in the cutting-edge manufacturing fields such as flexible display production, lithium battery processing, semiconductor wafer handling, and optical film conveying.

The Structural Components of Air-floating Roller

1. Roller body: the high-rigidity aluminum alloy or steel

2. Surface throttling layer: porous graphite and porous ceramic

3. Air supply system: the external regulated compressed air supply

4. Sensing module(optional): integrated displacement, temperature, and pressure sensors

The Technical Advantages of Air-floating Roller

1. Non-contact suspension support:

The conventional rollers may lead to product defects arising from mechanical friction caused by surface contact and mismatches between rotational speed and tension during operation. Different from conventional rollers, air-floating rollers can achieve full non-contact with the thin film materials during operation, which effectively avoids the possibility of contact-induced product defects and scratches.

2. Wrinkle Prevention:

The air-floating roller adopts optimized porous media material (e.g., porous graphite, porous ceramics) to stably generate a uniform and soft air film. By adaptively adjusting to the tension variations of thin film materials, this air film can maintains a constantly smooth surface of thin film materials, which can significantly eliminate the wrinkling issues caused by uneven contact or localized pressure concentration between the roller surface and the thin film materials.

3. High-temperature adaptability:

The non-contact operating of air-floating rollers can prevent friction-induced heat generation and avoid additional temperature buildup in high-temperature conditions. In this way, the thin film material avoids direct contact with the roller surface even under high-temperature conditions (e.g., drying and heat-setting sections), thus preventing issues such as thermal adhesion, scratching, and indentation. High temperatures can easily cause plastic films and flexible materials to wrinkle due to thermal expansion and contraction. The air-floating rollers provide a stable and uniform supporting air film, which can still resist localized wrinkles caused by thermal stress even at high temperatures.

Semicorex offers high-quality Porous Graphite for Air-floating Bearings. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com