- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

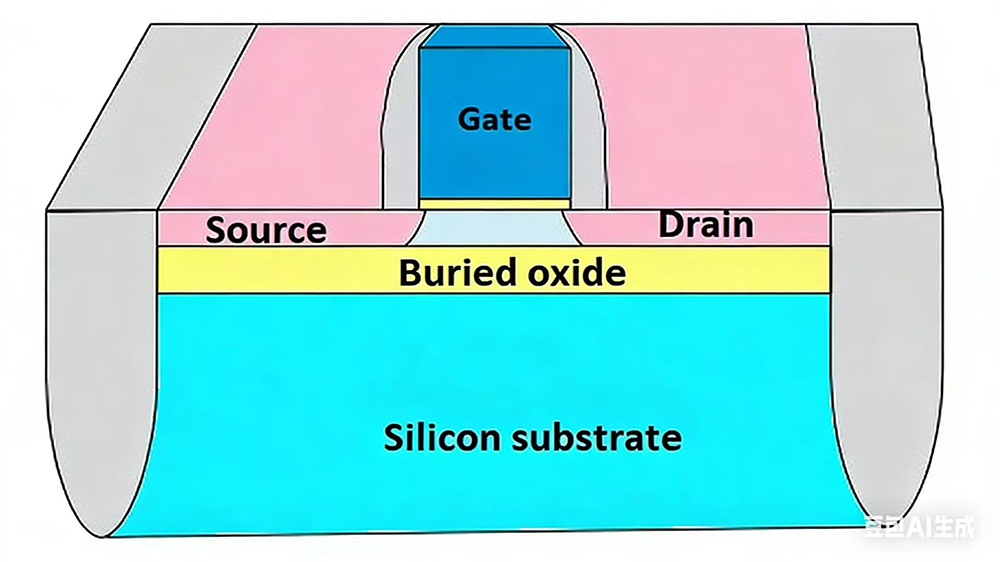

An Overview of SOI Substrates

SOI(Silicon-On-Insulator) substrate is structure in which a silicon oxide (SiO2) insulating layer is introduced between a top silicon layer and a silicon substrate, and integrated circuits are fabricated on the top silicon thin layer. This technology of using SOI materials to manufacture integrated circuits is called SOI technology.

The three main technologies for manufacturing SOI substrate

1. Separation by implanted oxygen (SIMOX)

2. Bond and etch-back SOI (BESOI)

3. Smart-cut technology.

The Advantages of SOI substrate

1. Low Substrate Leakage Current

The presence of a SiO2 insulating layer effectively isolates the transistor from the underlying silicon substrate. This isolation reduces unwanted current from the active layer to the substrate. Leakage current increases with temperature, thus significantly improving chip reliability in high-temperature environments.

2. Reduced Parasitic Capacitance

Due to the existence of parasitic capacitance, the additional delays are inevitably incurred in signal transmission. Using SOI materials to reduce these parasitic capacitances is common practice in high-speed or low-power chips. Compared to conventional chips manufactured using CMOS processes, SOI chips can achieve 15% higher speed and 20% lower power consumption.

3. Noise Isolation

In mixed-signal applications, electrical noise generated by digital circuitry may interfere with analog or radio frequency (RF) circuits, which will lead to a decrease in overall system performance. The SiO2 insulating layer in the SOI structure isolates the active silicon layer from the substrate, thus delivering an inherent noise isolation. This means that noise generated by digital circuitry can be effectively prevented from propagating through the substrate to sensitive analog circuitry.

The Application Areas of SOI substrate

1. Consumer electronics sector

Since SOI substrates can significantly improve the performance of devices like RF filters and power amplifiers and achieve faster signal transmission and lower power consumption. They are widely used in chip manufacturing for smart wearable devices like smartwatches and health monitoring devices, and RF front-end modules of mobile phones and tablets.

2. Automotive electronics

Thanks to the excellent performance to withstand complex electromagnetic conditions, SOI substrates is well-suited for the manufacture of automotive power management chips and applications in the autonomous driving systems.

3. Aerospace and defense sectors

SOI substrates offer remarkable reliability and resistance to radiation interference, and are able to meet the stringent requirements of satellite communication equipment and military electronic systems for high precision and high reliability.

4. Internet of Things (IoT)

With the surge in IoT data volume, the demand for low-cost and high-precision operation is growing. Benefiting from the low power consumption and high performance advantages, SOI substrates perfectly align with the IoT's requirements and are extensively adopted in the manufacturing of sensor node chips and edge computing chips.

5. Implantable Medical Devices in the Medical Electronics Field

Devices such as pacemakers and neurostimulators have extremely high requirements for low power consumption and biocompatibility. The low power consumption and stability of SOI substrates can ensure the long-term safe operation of implantable devices while minimizing the impact on the patient's body.