- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Solar Power Illuminates Life

At dawn, as the first rays of sunlight fall upon the rooftops of Karachi, Pakistan, the 15 solar panels in the home of 27-year-old Raza and his wife Mairam begin to quietly operate.

Karachi hosts several major solar photovoltaic exhibitions annually, making the city more receptive to solar power than other cities. A few months ago, the newlyweds' parents invested approximately 20,000 RMB to install this solar power system for them. Now, their new home can use solar power during the day and rely on the national power grid after sunset, reducing their monthly electricity bill from 1,500 RMB to 600 RMB. The installation took only three days, yet it has brought them numerous conveniences.

In Pakistan, where electricity is scarce and expensive, this new technology, capable of significantly reducing household expenses, is rapidly becoming a new standard in daily life, even evolving into a new trend in weddings that showcases economic strength and forward-thinking. With economic development, household appliances such as refrigerators, air conditioners, and washing machines are becoming increasingly common in Pakistan, placing a heavy burden on the aging and fragile traditional power grid, while electricity prices remain high. Thus, photovoltaic (PV) systems, capable of converting abundant sunlight into stable electricity, have rapidly transformed from a "novelty" into a "necessity" for addressing the energy crisis.

Silicon Carbide Ceramic in PV manufacturing

The market for PV manufacturing is also expanding, with silicon carbide ceramics being an indispensable high-precision material in PV production.

Silicon carbide is a high-performance high-temperature structural ceramic with advantages such as high strength, high hardness, high thermal conductivity, low coefficient of thermal expansion, and excellent oxidation resistance, corrosion resistance, and wear resistance, making it widely used in various downstream fields. However, silicon carbide is a material with strong covalent bonds, resulting in a relatively low atomic diffusion rate during sintering, and high grain boundary slip resistance and thermal stability. Therefore, sintering aids or special sintering processes, such as hot isostatic pressing, pressureless sintering, or reaction sintering, are typically required to achieve densification of silicon carbide.

The basic principle of reaction-bonded silicon carbide is as follows: reactive liquid silicon or silicon alloy, under capillary force, penetrates into a porous carbon-containing ceramic preform and reacts with the carbon to form silicon carbide. The newly formed silicon carbide binds in situ to the original silicon carbide particles in the preform, and the impregnating agent fills the remaining pores in the preform, completing the densification process. Compared with other preparation processes for silicon carbide ceramics, reaction-bonded silicon carbide ceramics have advantages such as low sintering temperature, near-net-shape forming, high hot strength, no deformation at high temperatures, high thermal conductivity, oxidation resistance, good chemical stability, and ultra-long service life, and have been widely used in various high-tech fields requiring high-temperature stability.

In the past decade or so, the rapid development of the photovoltaic industry has driven a significant increase in the market demand for reaction-bonded silicon carbide ceramics, and the number and scale of domestic reaction-bonded silicon carbide ceramic manufacturers have also increased year by year. After years of verification, reaction sintering silicon carbide technology has been successfully applied to the production of key ceramic components such as cantilever propellers and boat supports in the production process of second-generation and second-and-a-half-generation photovoltaic cells, effectively solving the problem of wear and tear on load-bearing components under high load conditions in photovoltaic cells.

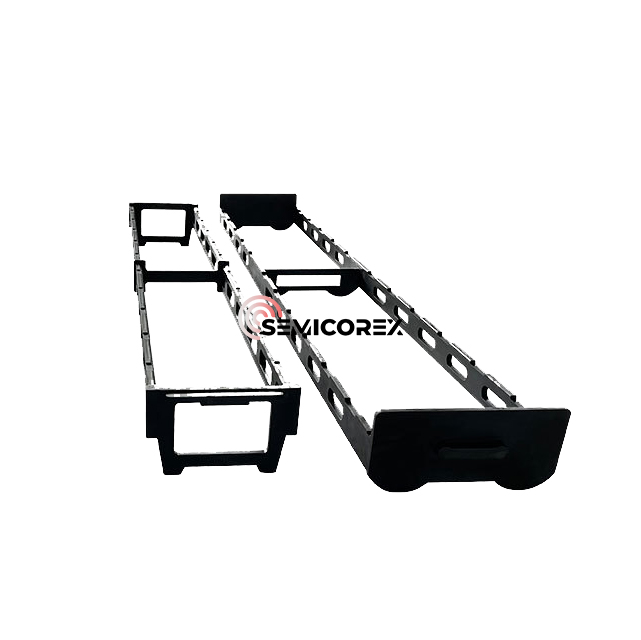

Semicorex offers customs SiC ceramic components, such as wafer boat, cantilever paddles, boat holder, and etc. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com