- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Why do the sidewalls bend during dry etching

2025-11-12

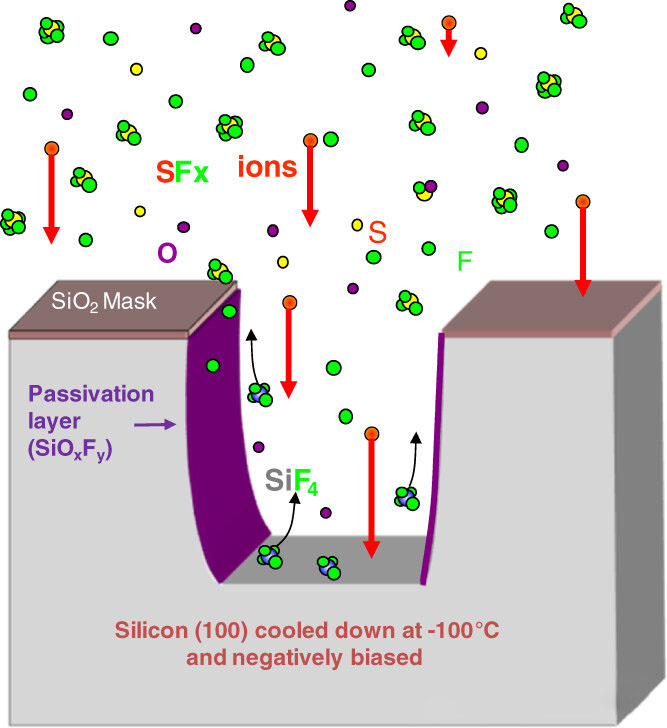

Dry etching is typically a process combining physical and chemical actions, with ion bombardment being a crucial physical etching technique. During etching, the incident angle and energy distribution of ions can be uneven.

If the ion incident angle varies at different locat ions on the sidewalls, the etching effect will also differ. In areas with larger ion incident angles, the ion etching effect on the sidewalls is stronger, leading to more sidewall etching in that area and causing sidewall bending. Furthermore, uneven ion energy distribution also produces a similar effect; higher-energy ions remove material more effectively, resulting in inconsistent etching levels at different locations on the sidewalls, further causing sidewall bending.

Photoresist acts as a mask in dry etching, protecting areas that do not need to be etched. However, photoresist is also affected by plasma bombardment and chemical reactions during etching, and its properties may change.

Uneven photoresist thickness, inconsistent consumption rates during etching, or variations in the adhesion between the photoresist and the substrate at different locations can all lead to uneven protection of the sidewalls during etching. For example, areas with thinner or weaker photoresist adhesion may allow the underlying material to be etched more easily, leading to sidewall bending at these locations.

Substrate Material Characteristics Differences

The substrate material being etched may exhibit differences in characteristics, such as varying crystal orientations and doping concentrations in different regions. These differences affect etching rates and selectivity.

Taking crystalline silicon as an example, the arrangement of silicon atoms differs across crystal orientations, resulting in variations in reactivity with the etching gas and etching rates. During etching, these differences in material properties lead to inconsistent etching depths at different locations on the sidewalls, ultimately causing sidewall bending.

Equipment-Related Factors

The performance and condition of the etching equipment also significantly impact the etching results. For instance, uneven plasma distribution within the reaction chamber and uneven electrode wear can cause uneven distribution of parameters such as ion density and energy on the wafer surface during etching.

Furthermore, uneven temperature control and minor fluctuations in gas flow rate can also affect etching uniformity, further contributing to sidewall bending.

Semicorex offers high-quality CVD SiC components for etching. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com