- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

The Core Parameters in Dry Etching

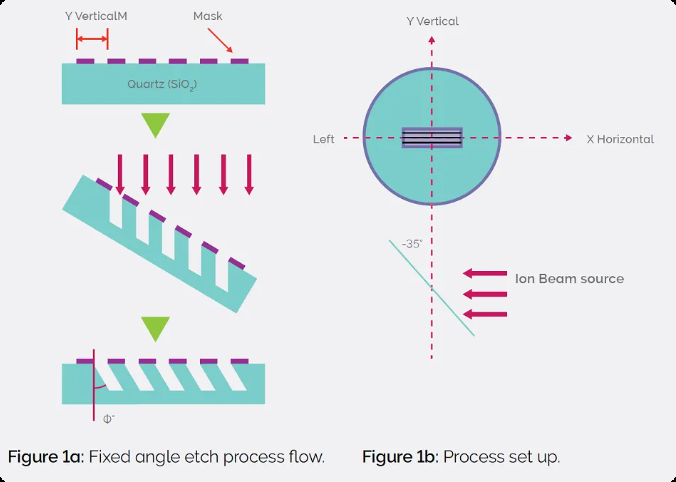

Dry etching is a main technology in the manufacturing processes of micro-electro-mechanical systems. The performance of dry etching process exerts a direct influence on the structural precision and operational performance of semiconductor devices. To precisely control the etching process, the close attention must be paid to the following core evaluation parameters.

1.Etch Rete

Etching rate refers to the thickness of material etched per unit time (units: nm/min or μm/min). Its value directly affects etching efficiency, and an low etching rate will prolong the production cycle. It should be noted that equipment parameters, material properties, and etching area all influence the etching rate.

2.Selectivity

Substrate selectivity and mask selectivity are the two types of dry etching selectivity. Ideally, the etching gas with high mask selectivity and low substrate selectivity should be chosen, but in reality, the choice must be optimized by considering the material properties.

3.Uniformity

Within-wafer uniformity is the rate consistency at different locations within the same wafer, leading to dimensional deviations in semiconductor devices. While wafer-to-wafer uniformity refers to the rate consistency between different wafers, which can cause batch-to-batch accuracy fluctuations.

4.Critical Dimension

The critical dimension refers to the geometric parameters of microstructures like line width, trench width, and hole diameter.

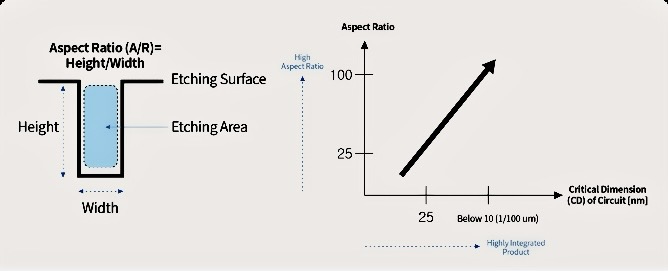

5.Aspect Ratio

The aspect ratio, as the name suggests, is the ratio of etching depth to aperture width. Aspect ratio structures are a core requirement for 3D devices in MEMS, and must be optimized through gas ratio and power control to avoid bottom rate degradation.

6.Etch Damage

Etch damage like over-etching, undercut and side etching can reduce dimensional accuracy (e.g., electrode spacing deviation, narrowing of cantilever beams).

7.Loading Effect

Loading effect refers to the phenomenon that the etching rate changes non-linearly with variables such as the area and linewidth of the etched pattern. In other words, different etched areas or linewidths will lead to differences in rate or morphology.

Semicorex specialize in SiC coated and TaC coated graphite solutions applied in Etching Processes in semiconductor manufacturing, if you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone: +86-13567891907

Email: sales@semicorex.com