- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

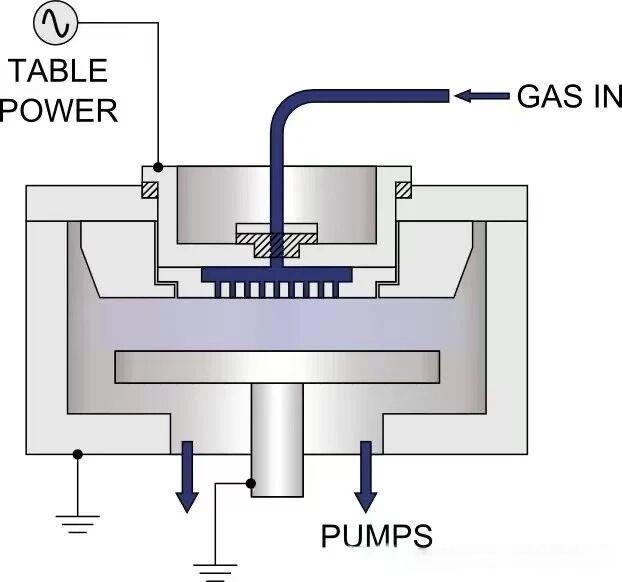

Showerheads in Etching

2025-10-13

Silicon carbide (SiC) showerheads are key components in semiconductor manufacturing equipment, playing a crucial role in advanced processes such as chemical vapor deposition (CVD) and atomic layer deposition (ALD).

The primary function of a SiC showerhead is to evenly distribute reactant gases across the wafer surface, ensuring uniform and consistent deposited layers. In CVD and ALD processes, uniform distribution of reactant gases is crucial for achieving high-quality thin films. The unique structure and material properties of SiC showerheads enable efficient gas distribution and uniform gas flow, meeting the stringent requirements for film quality and performance in semiconductor manufacturing.

During the wafer reaction process, the showerhead surface is densely covered with micropores (pore diameter 0.2-6 mm). Through a precisely designed pore structure and gas path, specialized process gases are passed through thousands of tiny holes in the gas distribution plate and evenly deposited on the wafer surface. This ensures highly uniform and consistent film layers across different regions of the wafer. Therefore, in addition to extremely high requirements for cleanliness and corrosion resistance, the gas distribution plate also places stringent demands on the consistency of the aperture diameter and the presence of burrs on the inner walls of the apertures. Excessive tolerance and consistency standard deviation of the aperture size, or the presence of burrs on any inner wall, will lead to uneven thickness of the deposited film, directly impacting the equipment's process yield. In plasma-assisted processes (such as PECVD and dry etching), the showerhead, as part of the electrode, generates a uniform electric field using an RF power source, promoting uniform plasma distribution and thus improving etching or deposition uniformity.

SiC showerheads are widely used in the manufacturing of integrated circuits, microelectromechanical systems (MEMS), power semiconductors, and other fields. Their performance advantages are particularly evident in advanced process nodes requiring high-precision deposition, such as 7nm and 5nm processes and below. They provide stable and uniform gas distribution, ensuring uniformity and consistency of the deposited layer, thereby improving the performance and reliability of semiconductor devices.

Semicorex offers customized CVD SiC and Silicon showerheads based on customers’ needs. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com