- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is recrystallized silicon carbide ceramic?

2025-10-11

Recrystallized silicon carbide is a high-performance ceramic formed by combining SiC particles through an evaporation-condensation mechanism to form a strong solid-phase sintered body. Its most notable feature is that no sintering aids are added, and the final product is almost pure silicon carbide, which gives it extremely excellent high-temperature performance and chemical stability.

Recrystallized silicon carbide ceramic fabrication process

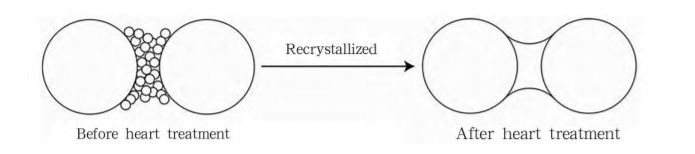

After high-purity silicon carbide powder of different particle sizes is graded in a certain ratio, the green body of the desired shape is formed by slip casting, press molding and extrusion molding. These green bodies are sintered at ultra-high temperatures (2100-2500°C) in an inert atmosphere (such as argon) or in a vacuum. In this environment, atoms on the surface of the SiC particles evaporate and then condense and deposit in the neck area of the particles, forming a strong connection at the contact point of the particles to form a sintered body. As a result, the recrystallized silicon carbide exhibits no shrinkage or liquid phase during the sintering process, ultimately forming a porous network skeleton structure with interconnected pores.

Characteristics and applications of recrystallized silicon carbide

RSiC contains more than 99% silicon carbide, has very clear grain boundaries, and basically does not contain glass phase and impurities. It has excellent high-temperature resistance, superior thermal shock resistance, outstanding oxidation resistance, and superb chemical corrosion resistance. It is suitable for use in high-temperature kiln furniture, burner nozzles, thermal converters, chemical industry, metal smelting and other environments with extremely stringent performance requirements.

Under this sintering mechanism, RSIC has a high porosity and low flexural strength at room temperature, which limits its application in structural parts with high room temperature strength requirements. However, due to the network skeleton structure of interconnected pores of this material, it has broad application prospects in the field of porous materials and can replace traditional porous products in the fields of exhaust gas filtration, fossil fuel air filtration, etc.