- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is Diffusion Process

2025-09-03

Doping involves introducing a dose of impurities into semiconductor materials to alter their electrical properties. Diffusion and ion implantation are two methods of doping. Early impurity doping was primarily accomplished through high-temperature diffusion.

Diffusion deposits impurity atoms onto the surface of a substrate wafer from a vapor source or doped oxide. The impurity concentration decreases monotonically from the surface to the bulk, and the impurity distribution is primarily determined by the diffusion temperature and time. Ion implantation involves injecting dopant ions into the semiconductor using an ion beam. The impurity concentration has a peak distribution within the semiconductor, and the impurity distribution is determined by the ion dose and implantation energy.

During the diffusion process, the wafer is typically placed in a strictly temperature-controlled quartz high-temperature furnace tube and a gas mixture containing the desired dopant is introduced. For Si diffusion processes, boron is the most commonly used p-type dopant, while phosphorus is the most commonly used n-type dopant. (For SiC ion implantation, the p-type dopant is typically boron or aluminum, and the n-type dopant is typically nitrogen.)

Diffusion in semiconductors can be viewed as the atomic movement of dopant atoms in the substrate lattice through vacancies or interstitial atoms.

At high temperatures, lattice atoms vibrate near their equilibrium positions. Atoms at lattice sites have a certain probability of gaining enough energy to move from their equilibrium positions, creating interstitial atoms. This creates a vacancy at the original site. When a nearby impurity atom occupies a vacant site, this is called vacancy diffusion. When an interstitial atom moves from one site to another, it's called interstitial diffusion. Atoms with smaller atomic radii generally experience interstitial diffusion. Another type of diffusion occurs when interstitial atoms displace atoms from nearby lattice sites, pushing a replacement impurity atom into the interstitial site. This atom then repeats this process, significantly accelerating the diffusion rate. This is called push-fill diffusion.

The primary diffusion mechanisms of P and B in Si are vacancy diffusion and push-fill diffusion.

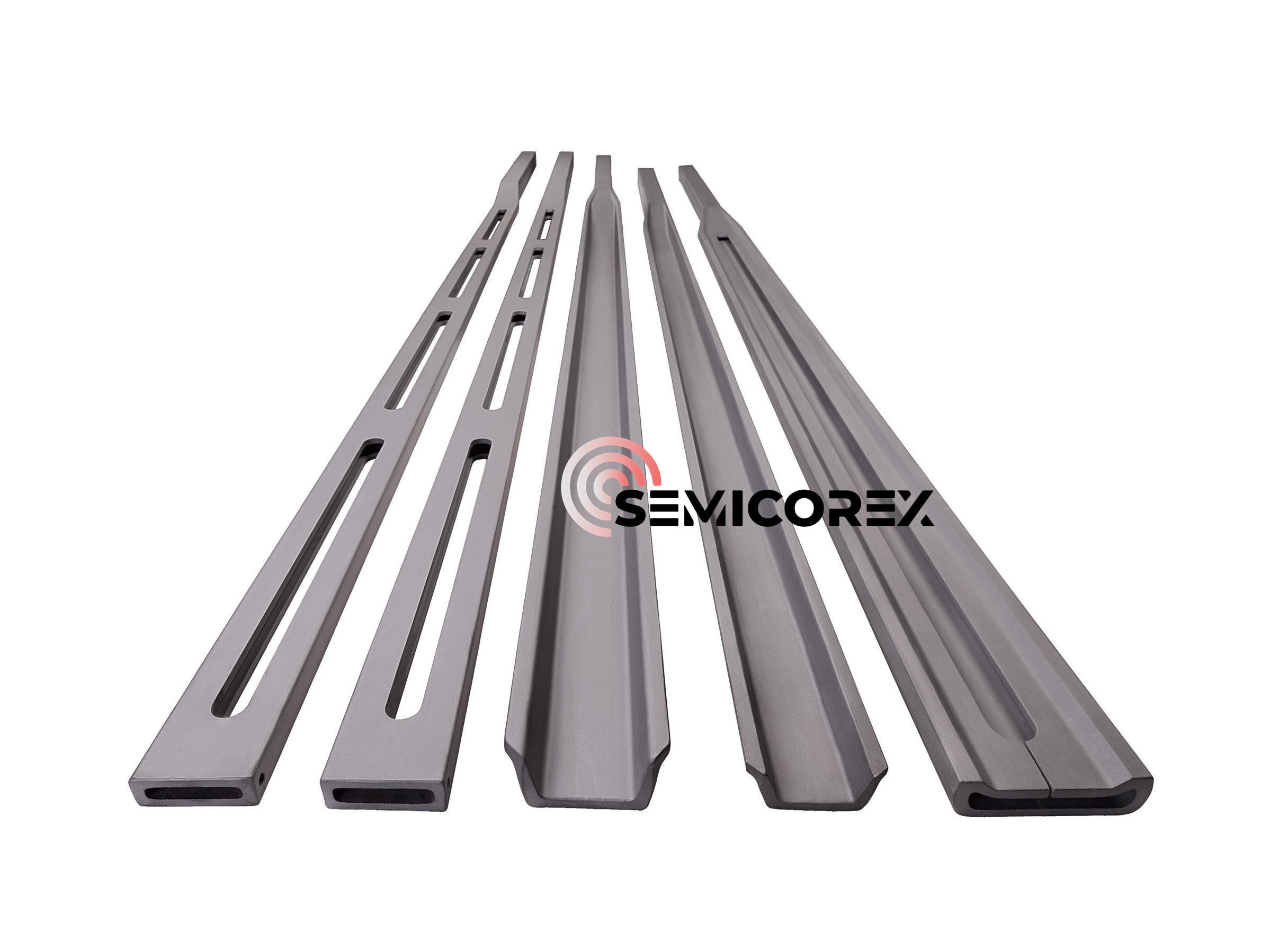

Semicorex offers high-purity customized SiC components in diffusion process. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com