- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is Silicon Carbide Disc Membrane

2025-09-10

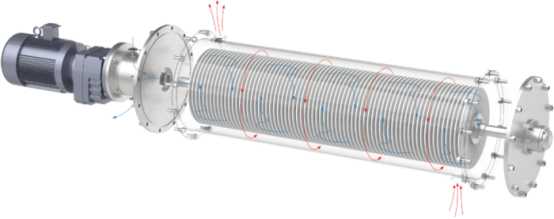

Currently, the ceramic membrane products on the market primarily consist of tubular and plate-type ceramic membranes. However, neither is suitable for high-viscosity, high-solids separation applications. Compared to flat and tubular ceramic membranes, disc-type ceramic membranes (DCMs) can generate high transmembrane flow velocities at low transmembrane pressures (TMPs) through the membrane's own rotation. This allows for independent control of transmembrane flow velocity and TMP, effectively reducing concentration polarization and mitigating membrane fouling, resulting in highly efficient filtration.

The disc-type ceramic membrane rotates along a high-precision shaft driven by a motor, generating high fluid velocities on the membrane surface and, in turn, strong shear, creating dynamic cross-flow filtration. Dynamic cross-flow filtration homogenizes the feed and alleviates concentration polarization. The dynamically generated shear stress and centrifugal force prevent the accumulation of fouling layers on the membrane surface. Therefore, the disc-type ceramic membrane's rotational pattern provides high transmembrane flow velocities while maintaining low transmembrane pressures, effectively controlling and delaying membrane fouling. This is the secret to the DCM's ability to handle high-viscosity, high-solids fluid separations.

Semicorex offers high-quality SiC disc membranes. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com