- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

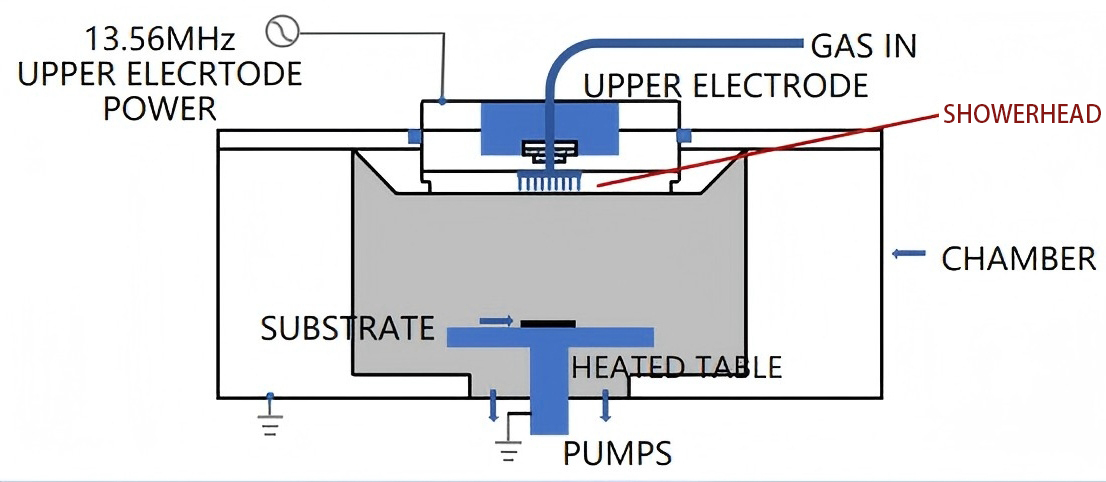

Semiconductor Showerheads

The gas distribution plate, often referred to as a "showerhead," may resemble a conventional showerhead, but its price can reach into the hundreds of thousands, significantly higher than a typical bathroom shower.

The surface of the gas distribution plate features hundreds or even thousands of tiny, precisely arranged holes, resembling a finely woven neural network. This design allows for accurate control of gas flow and injection angles, ensuring that every part of the wafer processing area is evenly "bathed" in process gas. This not only enhances production efficiency but also improves product quality.

The gas distribution plate is integral to key processes such as cleaning, etching, and deposition. It directly influences the accuracy of semiconductor processes and the quality of the final products, making it a critical component in various gas distribution applications.

During the wafer reaction process, the surface of the showerhead is densely covered with micropores (aperture 0.2-6 mm). Through the precisely designed channel structure and gas path, the special process gas needs to pass through thousands of small holes on the uniform gas plate and then be evenly deposited on the wafer surface. The film layer in different areas of the wafer needs to ensure high uniformity and consistency. Therefore, in addition to extremely high requirements for cleanliness and corrosion resistance, the gas distribution plate has strict requirements on the consistency of the aperture of the small holes on the gas distribution plate and the burrs on the inner wall of the small holes. If the aperture size tolerance and consistency standard deviation are too large or there are burrs on any inner wall, the thickness of the deposited film layer will be different, which will directly affect the process yield of the equipment.

The material of the gas distribution plate is sometimes brittle material (such as single crystal silicon, quartz glass, ceramics), which is easy to break under the action of external force. It is also an ultra-deep hole within 50 times the diameter of the micropore, and the cutting situation cannot be directly observed. In addition, the cutting heat is not easy to transmit and the chip removal is difficult, and the drill bit is easily broken due to chip blockage. Therefore, its processing and preparation is very difficult.

In addition, in plasma-assisted processes (such as PECVD and dry etching), the shower head, as part of the electrode, also needs to generate a uniform electric field through an RF power supply to promote uniform distribution of plasma, thereby improving the uniformity of etching or deposition.

Since the gases used in the semiconductor manufacturing process may be high temperature, high pressure or corrosive, the showerhead is usually made of corrosion-resistant materials. In actual production, due to different usage scenarios and actual required precision, the gas distribution plate can be divided into the following two categories according to its material composition:

(1) Metal gas distribution plate

The materials of metal gas distribution plates include aluminum alloy, stainless steel and nickel metal, among which the most widely used metal gas distribution plate material is aluminum alloy, because it has good thermal conductivity and strong corrosion resistance. It is widely available and easy to process.

(2) Non-metallic gas distribution plate

The materials of non-metallic gas distribution plates include single crystal silicon, quartz glass and ceramic materials. Among them, the commonly used ceramic materials are CVD-SiC, alumina ceramics, silicon nitride ceramics, etc.

Semicorex offers high-quality CVD SiC showerheads in semiconductor industry. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com