- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

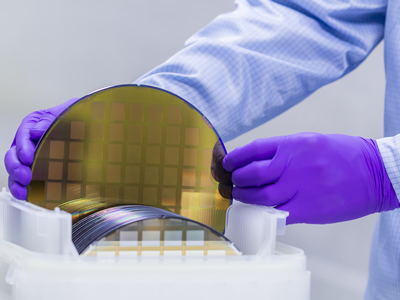

Horizontal Wafer Cassette

Semicorex Horizontal Wafer Cassette is an essential tool in the semiconductor manufacturing industry, offering significant advantages in wafer protection, contamination control, and processing efficiency.

Send Inquiry

Material Properties

The Semicorex Horizontal Wafer Cassette is a vital tool in the semiconductor industry for protecting and handling wafers at different phases of production. Often called wafer carriers, these cassettes are designed to hold and move several wafers of the same size. They ensure excellent performance in a variety of production conditions by meeting specific process requirements, such as thermal processing, and are available in a wide range of materials.

Various Material Choices

Horizontal Wafer Cassettes come in a variety of high-performance materials to satisfy the diverse requirements of semiconductor fabrication. These provide outstanding chemical resistance and thermal stability and include PVDF, ECTFE Halar, PFA Teflon, and PTFE Teflon. Options of stainless steel like 304L and 316 are recommended for applications needing increased mechanical strength and resistance to corrosion. Natural polypropylene is also used because of its economical and lightweight characteristics, which allow for flexibility in application while preserving the integrity of the wafer handling procedure.

Features of Advanced Design

With characteristics that can be adjusted to meet certain operational requirements, horizontal wafer cassettes are painstakingly constructed. These consist of side opening profiles, substrate contact points, substrate pitch and spacing, and sizes and shapes that can be altered. Their adaptability in a variety of processes is increased by their versatility in substrate orientation and capacity to handle a range of substrate sizes. Moreover, automation features and cassette handling capabilities, such as detachable handles for enhanced convenience, can be added to these cassettes.

Applications

In semiconductor manufacturing, the use of horizontal wafer cassettes is essential for guaranteeing the secure and effective handling of wafers in a variety of procedures.

Horizontal Wafer Cassettes are made of sturdy, high-quality materials and offer strong defence against physical damage and contamination, two major issues in semiconductor settings. The architecture of the cassettes protects the fragile wafers during storage and transportation by reducing exposure to any contaminants.

Improved Cleaning and Drying

Better washing and drying results are made possible by the huge opening area in the design of horizontal wafer cassettes. This characteristic is crucial for preserving wafer cleanliness, which lowers the possibility of flaws and improves the calibre of the finished semiconductor devices.

Efficiency of Chemical Flow and Processing

In order to minimise material trap spots and maximise chemical flow-through dynamics, horizontal wafer cassettes are designed. To improve chemical flow and guarantee complete coverage and efficient processing in chemical baths, a number of extra features can be added.

Safe Transport and Alignment of Wafers

The Horizontal Wafer Cassette design is characterised by precise wafer alignment, which guarantees that wafers are maintained firmly in position during transportation. This lowers the possibility of breakage or misalignment, which could result in expensive flaws or delays in the process. Wafer handling must be done securely in order to preserve the integrity of the semiconductor manufacturing process.

Efficiency in Workflow and Ergonomics

Horizontal Wafer Cassettes are easy to use and efficient due to their ergonomic design, which streamlines the loading and unloading procedure. In cleanroom settings, this simplicity of use improves workflow efficiency, enabling more efficient processes and less handling time. Manufacturers of semiconductors can increase efficiency and uphold strict cleanliness standards by simplifying these procedures.