- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

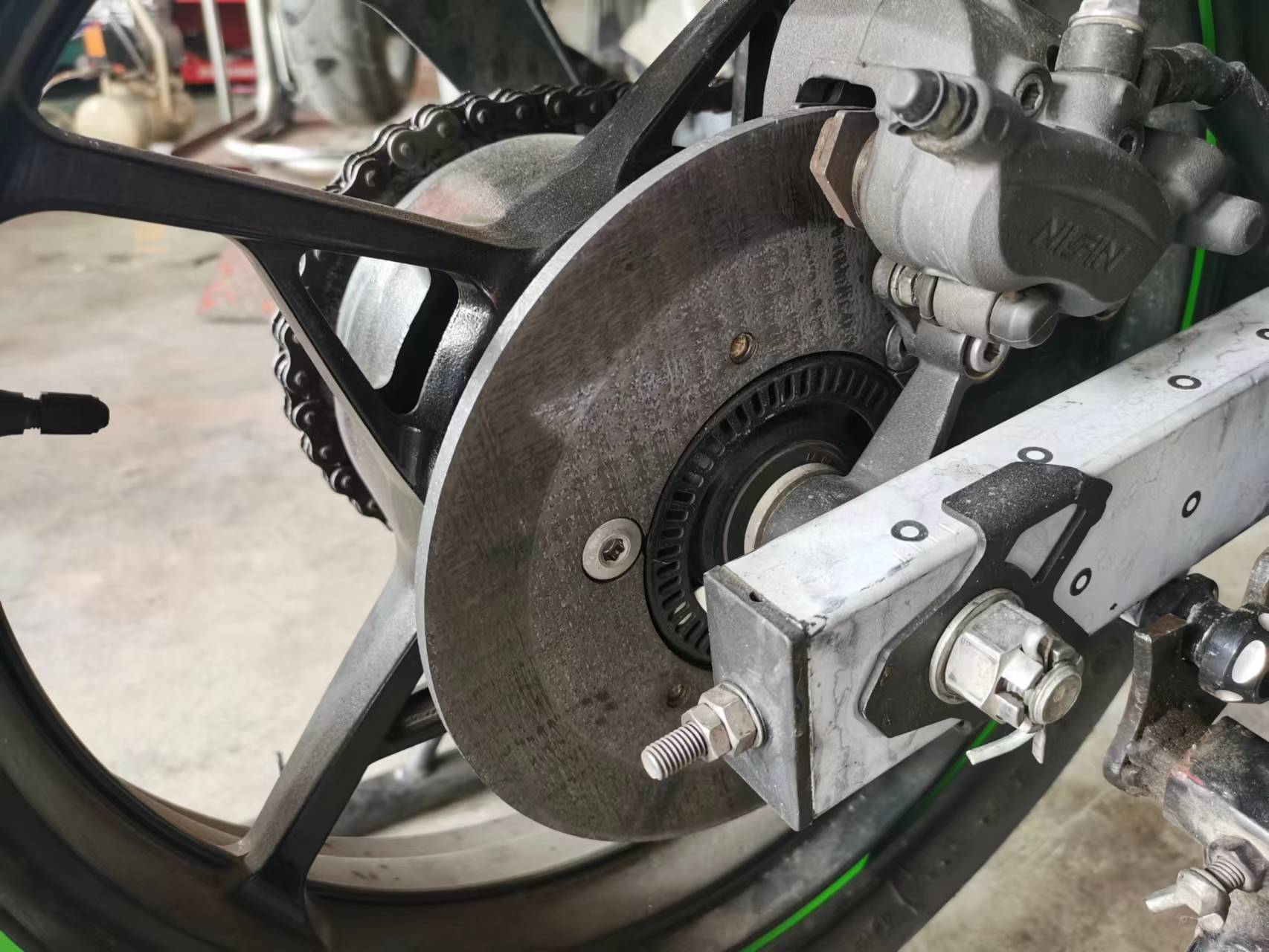

CCM Brakes

Semicorex CCM Brakes, made from advanced carbon-ceramic matrix materials, are the ideal solution for high-performance braking in extreme driving environments. Choose Semicorex for our unmatched expertise in ceramic composite engineering, precision manufacturing, and commitment to delivering consistent, race-proven quality.*

Send Inquiry

Semicorex CCM Brakes, or Carbon-Ceramic Matrix Brakes, are the latest development in the next generation of brakes, designed for high-performance cars that require the best thermal stability, lightwei

ght, and long durability. Made of a composite that consists of carbon fiber embedded in a ceramic silicon carbide (SiC) matrix, CCM Brakes have the best characteristics of both ceramics and carbon, offering the greatest stopping power under extreme conditions.

The three-dimensional felt or braid of carbon fiber is used as the reinforcing skeleton, and the matrix is composed of carbon (C) and silicon carbide (SiC). It is a dual-matrix composite material. It combin

es the advantages of carbon materials and silicon carbide, and has high toughness, low density, good thermal stability, thermal shock resistance, high hardness, high wear resistance and good oxidation resistance. In high temperature environments, the carbon matrix can provide a certain buffer and toughness to prevent the material from brittle cracking, and can withstand a high temperature of at least 1650°C.

CCM Brakes have a carbon-ceramic core. The production involves making a carbon fiber preform that is infiltrated by silicon at elevated temperatures. The result is a dense, strong ceramic matrix {silicon carbide). It is a brake disc that is much lighter than cast iron, but is incredibly strong and can withstand more than 1,200°C with no warping or fading.

The most significant advantage of CCM Brakes is resistance to heat and thermal cycling. Unlike steel or iron rotors, CCM Brakes have consistent braking power even if high performance braking is required, such as at a racetrack or during a high-speed descent. The superior thermal conductivity of the silicon carbide matrix allows for rapid heat dissipation, minimizing the risk of thermal damage and improving safety and stability during aggressive driving.

In addition to thermal resilience, CCM Brakes offer a major reduction in weight—typically up to 50% lighter than iron discs. This reduction in unsprung mass contributes to improved vehicle dynamics, including sharper handling, better suspension response, and enhanced fuel efficiency. The lower rotational inertia also enables faster acceleration and more efficient braking, making CCM Brakes a favorite in the world of supercars, motorsports, and luxury motorcycles.

Moreover, a hallmark of CCM Brakes is superior wear resistance. CCM Brakes typically last much longer than similarly constructed metallic disc designs, providing significant replacement value and reducing overall life cycle costs for the performance-based user. Further, carbon-ceramic materials exhibit corrosion resistance, and therefore, CCM Brakes provides consistent and stable braking power in humid and saline environments.

At Semicorex, we manufacture CCM Brakes to the highest purity and precision in material composition and processing, respectively. Our ceramic engineering expertise in combination with quality assurance procedures ensure uniformity of microstructure, great balance, and specific fitment for various vehicle applications. We work to build new and customize braking engineering solutions with OEMs and aftermarket performance brands that exceed performance benchmarks for speed, safety, and appearance.

In conclusion, CCM Brakes made from carbon-ceramic composite materials, with the lightness and durability of a performance bicycle, represent the top tier of choices for enthusiasts and manufacturers looking for lightweight, low-maintenance high-performance braking systems. As we have always been dedicated to customer solutions through excellence at Semicorex, we provide precision stopping power Incredibly Important! During the race, the road, and beyond!