- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

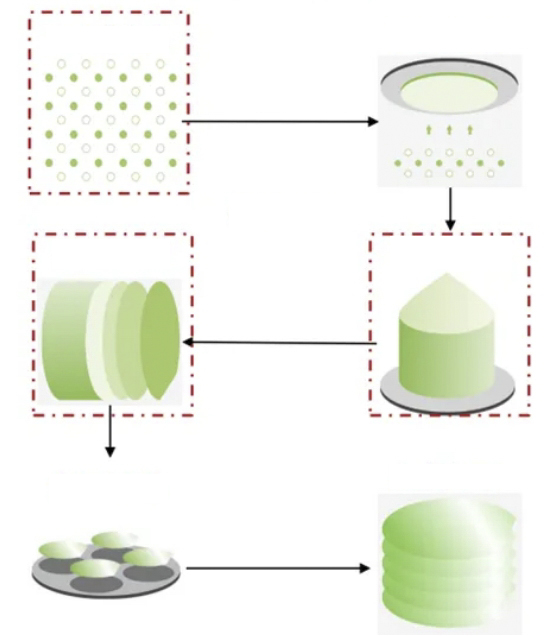

Substrate Cutting and Grinding Process

SiC substrate material is the core of SiC chip. The production process of the substrate is: after obtaining the SiC crystal ingot through single crystal growth; then preparing the SiC substrate requires smoothing, rounding, cutting, grinding (thinning); mechanical polishing, chemical mechanical poli......

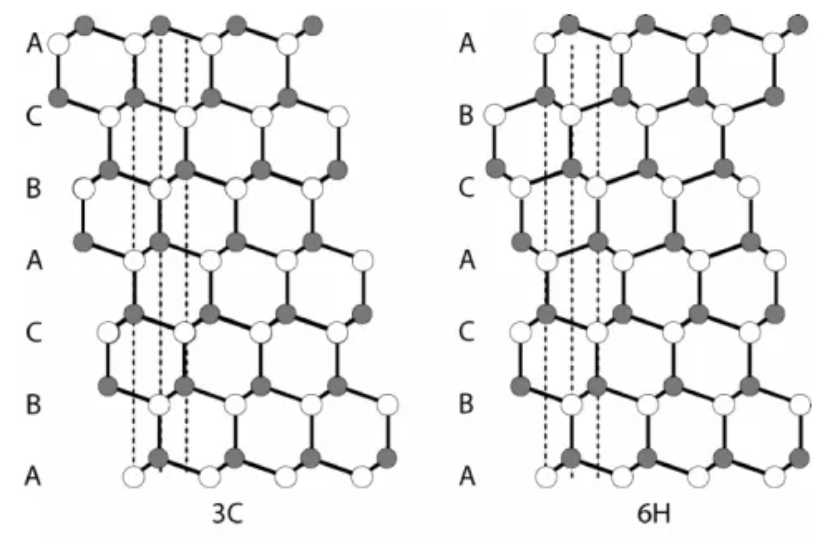

Read MoreDifferences between SiC crystals with different structures

Silicon carbide (SiC) is a material that possesses exceptional thermal, physical and chemical stability, exhibiting properties that go beyond those of conventional materials. Its thermal conductivity is an astonishing 84W/(m·K), which is not only higher than copper but also three times that of silic......

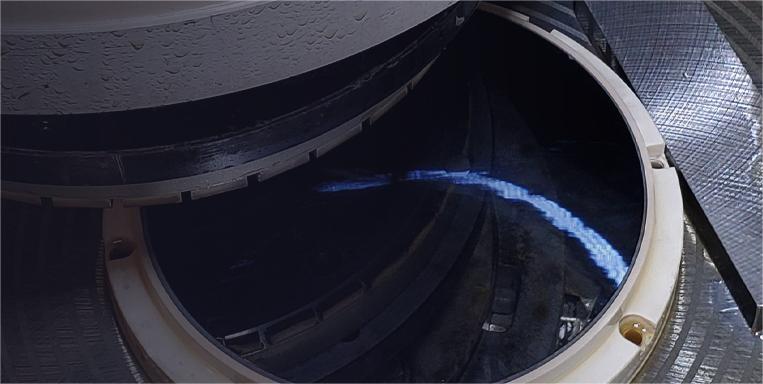

Read MoreWhat is a TaC coating on graphite?

In the rapidly evolving field of semiconductor manufacturing, even the smallest improvements can make a big difference when it comes to achieving optimal performance, durability, and efficiency. One advancement that is generating a lot of buzz in the industry is the use of TaC (Tantalum Carbide) coa......

Read MoreSilicon Carbide Industry

The silicon carbide industry involves a chain of processes that include substrate creation, epitaxial growth, device design, device manufacturing, packaging, and testing. In general, silicon carbide is created as ingots, which are then sliced, ground, and polished to produce a silicon carbide substr......

Read MoreCan you grind silicon carbide?

Silicon carbide (SiC) has important applications in areas such as power electronics, high-frequency RF devices, and sensors for high-temperature-resistant environments due to its excellent physicochemical properties. However, the slicing operation during SiC wafer processing introduces damages on th......

Read MoreGaN vs SiC

There are several materials currently under investigation, among which silicon carbide stands out as one of the most promising. Similar to GaN, it boasts higher operating voltages, higher breakdown voltages, and superior conductivity compared to silicon. Moreover, thanks to its high thermal conducti......

Read More