- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Alumina Substrates for Electronic Packaging

2025-09-19

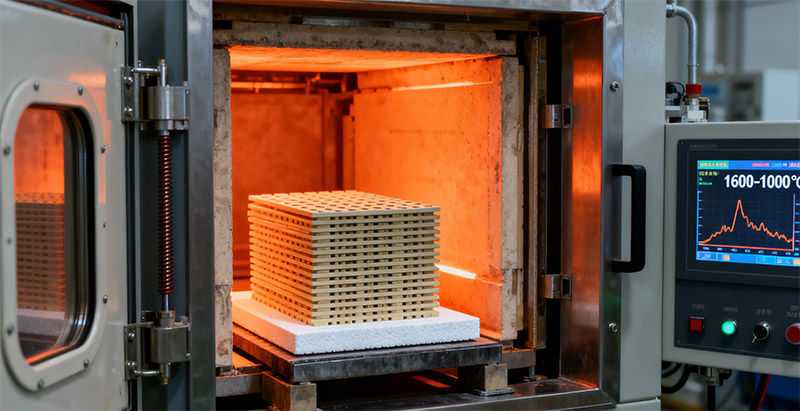

With the rapid development of fifth-generation mobile communications (5G), the Internet of Things, and power electronics, electronic components are evolving towards miniaturization, high integration, and high frequency and speed. This places higher demands on thermal management, insulation reliability, and signal integrity in circuit packaging materials. Alumina ceramics, with their high mechanical strength, excellent insulation properties, good thermal conductivity (approximately 20-30 W/(m·K)), low dielectric loss, and exceptional thermal shock resistance and chemical stability, have become an irreplaceable, key foundational material in electronic packaging. Coupled with their wide availability of raw materials, relatively low cost, and mature manufacturing processes, alumina ceramic substrates play a vital role in a wide range of applications, including aerospace, new energy vehicles, industrial control, and consumer electronics.

Alumina (Al₂O₃) exists in various isomorphous forms, including α-Al₂O₃, β-Al₂O₃, and γ-Al₂O₃. α-Al₂O₃ (corundum structure) is the most stable. Its crystal system belongs to the trigonal system, with oxygen ions in a hexagonal close-packed pattern and aluminum ions filling two-thirds of the octahedral voids, forming a dense, stable structure with high bonding strength. This structure endows α-Al₂O₃ with high hardness (Mohs hardness 9), a high melting point (approximately 2050°C), excellent chemical inertness, and dielectric properties, making it a preferred choice for manufacturing high-performance ceramic substrates.

Based on the purity of alumina, common ceramics are classified as: corundum porcelain (Al₂O₃ ≥ 99%), 99% porcelain, 95% porcelain, and 90% porcelain. High-alumina porcelain is generally defined as containing more than 85% Al₂O₃. As Al₂O₃ purity increases, the mechanical, thermal, and electrical properties of the ceramic significantly improve. For example, typical properties of 99.5% alumina ceramics include a bulk density of approximately 3.95 g/cm³, a flexural strength of 395 MPa, a linear expansion coefficient (25-800°C) of 8.1 × 10⁻⁶/°C, a thermal conductivity of 32 W/(m·K), a dielectric strength of 18 kV/mm, and a volume resistivity (at 25°C) exceeding 10¹⁴ Ω·cm. These properties make them ideal for electronic packaging applications requiring high power, high insulation, and high temperatures.

Semicorex offers high-quality Alumina substrates based on customers’ needs. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com