- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Industry News

What is Thermal Field?

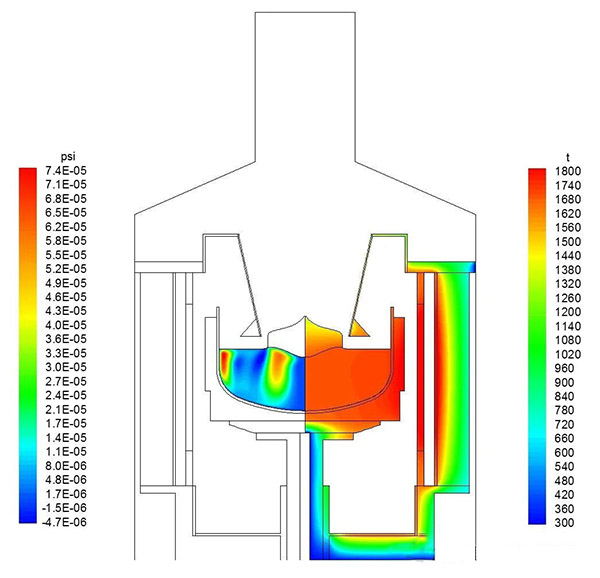

In the field of single crystal growth, the temperature distribution within the crystal growth furnace plays a critical role. This temperature distribution, commonly referred to as the thermal field, is a vital factor that influences the quality and characteristics of the crystal being grown. The the......

Read MoreIsostatic Graphite Production Technology

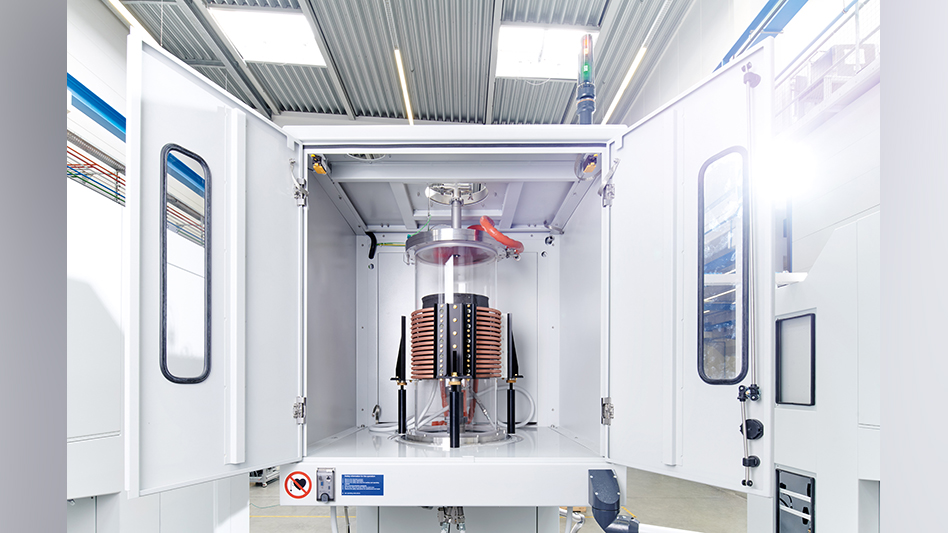

Isostatic pressing technology is a critical process in the manufacturing of isostatic graphite, largely determining the performance of the final product. As such, comprehensive research and optimization of isostatic graphite production remain essential focal points in the industry.

Read MoreResearch Progress of TaC Coatings on Carbon-Based Material Surfaces

Carbon-based materials such as graphite, carbon fibers, and carbon/carbon (C/C) composites are known for their high specific strength, high specific modulus, and excellent thermal properties, making them suitable for a wide range of high-temperature applications. These materials are widely utilized ......

Read MoreWhat Applications of Gallium Nitride (GaN) Substrate?

Gallium Nitride (GaN) is an important material in semiconductor technology, known for its exceptional electronic and optical properties. GaN, as a wide-bandgap semiconductor, has a bandgap energy of approximately 3.4 eV, making it ideal for high-power and high-frequency applications.

Read MoreTechnical Challenges in Silicon Carbide Crystal Growth Furnaces

Silicon carbide (SiC) crystal growth furnaces are the cornerstone of SiC wafer production. While sharing similarities with traditional silicon crystal growth furnaces, SiC furnaces face unique challenges due to the material’s extreme growth conditions and complex defect formation mechanisms. These c......

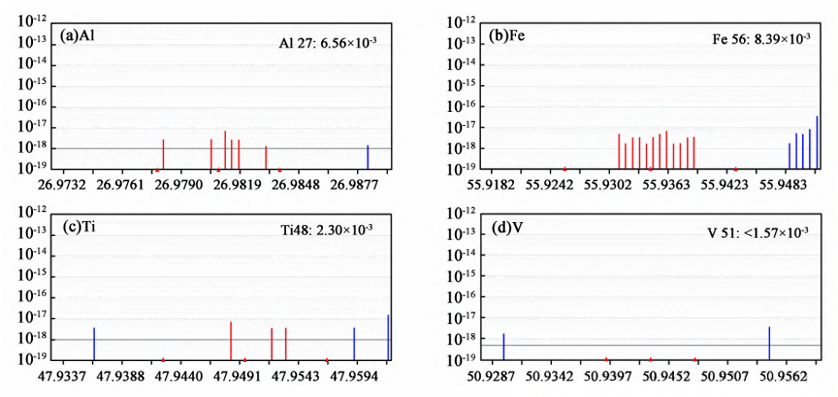

Read MorePurification Technology of Graphite in SiC semiconductor

Graphite is vital in producing Silicon Carbide (SiC) semiconductors, known for their exceptional thermal and electrical properties. This makes SiC ideal for high-power, high-temperature, and high-frequency applications. In SiC semiconductor manufacturing, graphite is commonly used for crucibles, hea......

Read More