- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is the Chemical Vapor Deposition?

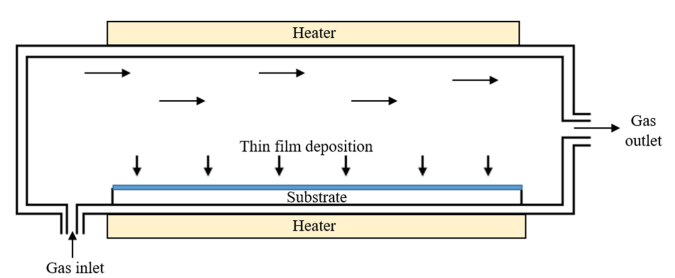

Chemical vapor deposition (CVD) is a coating technology that uses gaseous or vaporous substances to undergo chemical reactions in the gas phase or at a gas-solid interface to generate solid substances that are deposited on the substrate surface, thereby forming high-performance solid films. The core of CVD is to transport gaseous precursors into a reaction chamber, where chemical reactions generate solid products that are deposited on the substrate, and by-product gases are exhausted from the system.

The reaction process of CVD

1.Reaction precursors are delivered into the reaction chamber by a carrier gas. Before reaching the substrate, the reaction gases may undergo homogeneous gas-phase reactions in the main gas flow, generating some intermediate products and clusters.

2.Reactants and intermediate products diffuse through the boundary layer and are transported from the main airflow area to the substrate surface. Reactant molecules are adsorbed on the high-temperature substrate surface and diffuse along the surface.

3.The adsorbed molecules undergo heterogeneous surface reactions on the substrate surface, such as decomposition, reduction, oxidation, etc., to generate solid products (film atoms) and gaseous by-products.

4.Solid product atoms nucleate on the surface and serve as growth points, continuing to capture new reaction atoms through surface diffusion, achieving island growth of the film and ultimately fusion into a continuous film.

5.The gaseous by-products generated by the reaction desorb from the surface, diffuse back into the main gas flow, and are eventually discharged from the reaction chamber by the vacuum system.

Common CVD techniques include thermal CVD, Plasma-Enhanced CVD (PECVD), Laser CVD (LCVD), Metal-Organic CVD (MOCVD), Low-Pressure CVD (LPCVD), and High-Density Plasma CVD (HDP-CVD), which have their own advantages and can be selected according to specific demand.

CVD technologies can compatible with ceramics, glass, and alloys substrates. And it is especially suitable for deposition on complex substrates and can effectively coat challenging areas like sealed regions, blind holes, and internal surfaces. CVD possesses fast deposition rates while enabling precise control over film thickness. Films produced via CVD are of superior quality, featuring excellent uniformity, high purity, and strong adhesion to the substrate. They also demonstrate strong resistance to both high and low temperatures, as well as tolerance to extreme temperature fluctuations.

Several CVD SiC products provided by Semicorex. If you are interested, please feel free to contact us.