- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What are the technical difficulties of SiC crystal growth furnace

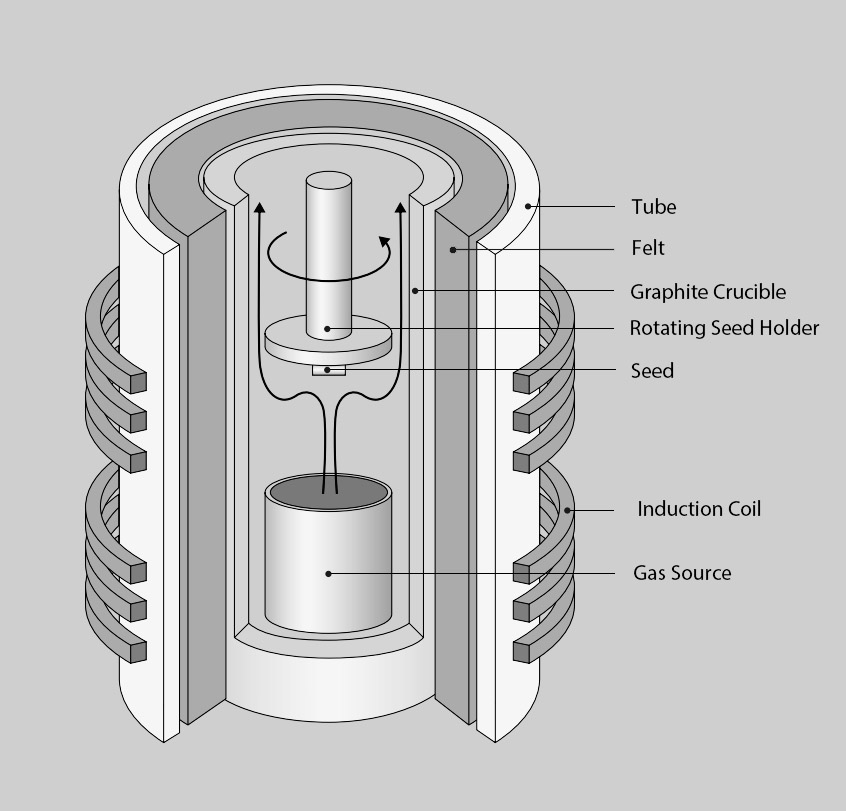

The crystal growth furnace is the core equipment for the growth of Silicon Carbide crystals. It is similar to the traditional crystalline silicon-grade crystal growth furnace. The furnace structure is not very complicated. It is mainly composed of the furnace body, heating system, coil transmission mechanism, vacuum acquisition and measurement system, gas path system, cooling system, control system, etc. The thermal field and process conditions determine the key indicators such as the quality, size, and conductivity of the SiC crystal.

On the one hand, the temperature during the growth of silicon carbide crystals is very high and cannot be monitored, so the main difficulty lies in the process itself. The main difficulties are as follows:

(1)Difficulty in thermal field control: The monitoring of the closed high-temperature chamber is difficult and uncontrollable. Unlike traditional silicon-based solution-based direct-pull crystal growth equipment, which has a high degree of automation and the crystal growth process can be observed, controlled and adjusted, silicon carbide crystals grow in a closed space in a high-temperature environment above 2,000°C, and the growth temperature needs to be precisely controlled during production, which makes temperature control difficult;

(2)Difficulty in crystal form control: Defects such as micropipes, polymorphic inclusions, and dislocations are prone to occur during the growth process, and they affect and evolve with each other. Micropipes (MPs) are through-type defects ranging from a few microns to tens of microns in size, and are killer defects for devices. Silicon carbide single crystals include more than 200 different crystal forms, but only a few crystal structures (4H type) are the semiconductor materials required for production. Crystal form transformation is prone to occur during growth, resulting in polymorphic inclusion defects. Therefore, it is necessary to precisely control parameters such as the silicon-carbon ratio, growth temperature gradient, crystal growth rate, and air flow pressure. In addition, there is a temperature gradient in the thermal field of silicon carbide single crystal growth, which leads to native internal stress and the resulting dislocations (basal plane dislocation BPD, screw dislocation TSD, edge dislocation TED) during crystal growth, thereby affecting the quality and performance of subsequent epitaxy and devices.

(3)Difficulty in doping control: The introduction of external impurities must be strictly controlled to obtain a conductive crystal with directionally doped structure.

(4)Slow growth rate: The growth rate of silicon carbide is very slow. Conventional silicon materials only need 3 days to grow into a crystal rod, while silicon carbide crystal rods need 7 days. This leads to naturally lower silicon carbide production efficiency and very limited output.

On the other hand, the parameters required for silicon carbide epitaxial growth are extremely high, including the airtightness of the equipment, the stability of the gas pressure in the reaction chamber, the precise control of the gas introduction time, the accuracy of the gas ratio, and the strict management of the deposition temperature. In particular, with the improvement of the device's voltage rating, the difficulty of controlling the core parameters of the epitaxial wafer has increased significantly. In addition, as the thickness of the epitaxial layer increases, how to control the uniformity of the resistivity and reduce the defect density while ensuring the thickness has become another major challenge. In the electrified control system, it is necessary to integrate high-precision sensors and actuators to ensure that various parameters can be accurately and stably controlled. At the same time, the optimization of the control algorithm is also crucial. It needs to be able to adjust the control strategy in real time according to the feedback signal to adapt to various changes in the silicon carbide epitaxial growth process.

Semicorex offers high-purity customized ceramic and graphite components in SiC crystal growth. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com