- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

TaC coated crucible in SiC crystal growth

2025-03-07

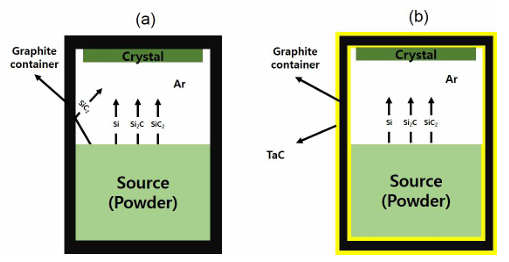

In recent years, TaC coated crucibles have become an important technical solution as reaction vessels in the growth process of silicon carbide (SiC) crystals. TaC materials have become key materials in the field of silicon carbide crystal growth due to their excellent chemical corrosion resistance and high temperature stability. Compared with traditional graphite crucibles, TaC coated crucibles provide a more stable growth environment, reduce the impact of graphite corrosion, extend the service life of the crucible, and effectively avoid the phenomenon of carbon wrapping, thereby reducing the density of microtubes.

Fig.1 SiC crystal growth

Advantages and Experimental Analysis of TaC-Coated Crucibles

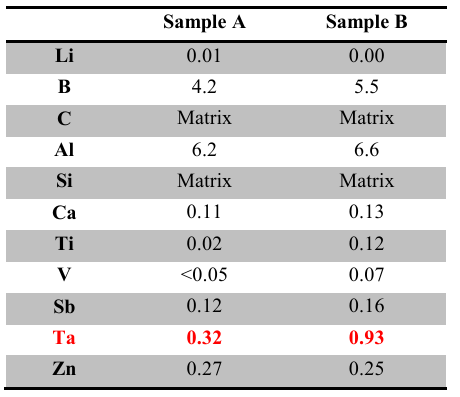

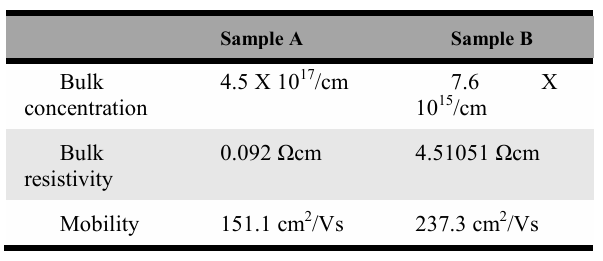

In this study, we compared the growth of silicon carbide crystals using traditional graphite crucibles and graphite crucibles coated with TaC. The results showed that TaC-coated crucibles significantly improve the quality of the crystals.

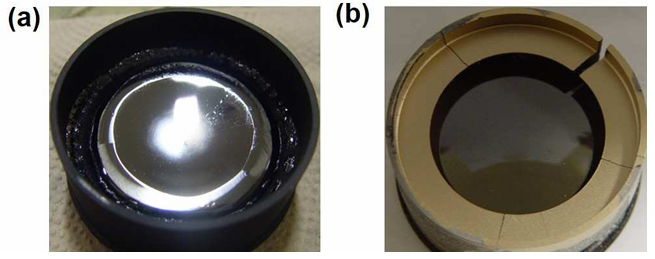

Fig.2 OM image of SiC ingot grown by PVT method

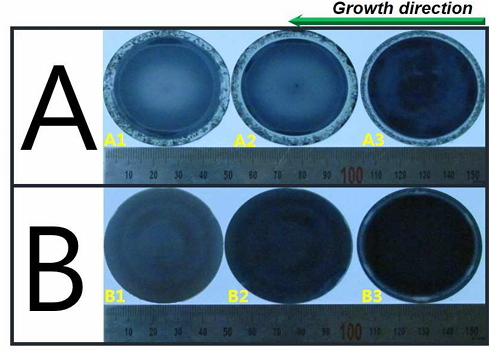

Figure 2 illustrates that silicon carbide crystals grown in traditional graphite crucibles display a concave interface, while those grown in TaC-coated crucibles exhibit a convex interface. Moreover, as seen in Figure 3, the edge polycrystalline phenomenon is pronounced in crystals grown using traditional graphite crucibles, whereas the use of TaC-coated crucibles effectively mitigates this issue.

The analysis indicates that the TaC coating raises the temperature at the edge of the crucible, thereby reducing the growth rate of crystals in that area. Additionally, the TaC coating prevents direct contact between the graphite side wall and the crystal, which helps mitigate nucleation. These factors collectively reduce the likelihood of polycrystallinity occurring at the edges of the crystal.

Fig.3 OM images of wafers at different growth stages

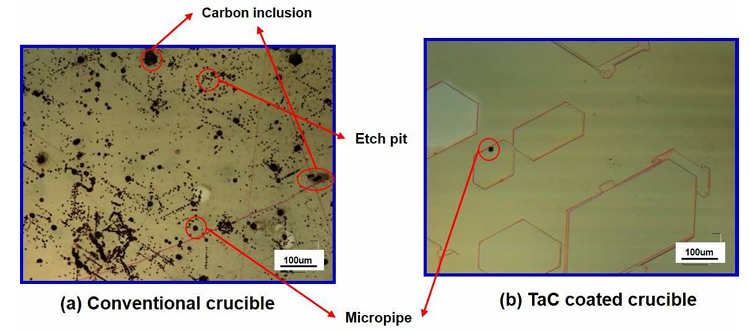

Furthermore, the silicon carbide crystals grown in TaC-coated crucibles exhibited almost no carbon encapsulation, a common cause of micropipe defects. As a result, these crystals demonstrate a significant reduction in micropipe defect density. Corrosion test results presented in Figure 4 confirm that crystals grown in TaC-coated crucibles have virtually no micropipe defects.

Fig.4 OM image after KOH etching

Improvement of crystal quality and impurity control

Through GDMS and Hall tests of crystals, the study found that the Ta content in the crystal increased slightly when TaC coated crucibles were used, but the TaC coating significantly limited the ingress of nitrogen (N) doping into the crystal. In summary, TaC coated crucibles can grow silicon carbide crystals with higher quality, especially in reducing defect density (especially microtubes and carbon encapsulation) and controlling nitrogen doping concentration.

Semicorex offers high-quality TaC-coated graphite crucible for SiC crystal growth. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com