- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What is Silicon Epitaxy Process?

2025-11-14

Silicon epitaxy is a primary fabrication process for integrated circuits. It allows IC devices to be fabricated on lightly doped epitaxial layers with heavily doped buried layers, while also forming grown PN junctions, thus solving the isolation problem of ICs. Silicon epitaxial wafers are also a primary material for fabricating discrete semiconductor devices because they can ensure high breakdown voltage of PN junctions while reducing the forward voltage drop of devices. Using silicon epitaxial wafers to fabricate CMOS circuits can suppress latch-up effects, therefore, silicon epitaxial wafers are increasingly widely used in CMOS devices.

The Principle of Silicon Epitaxy

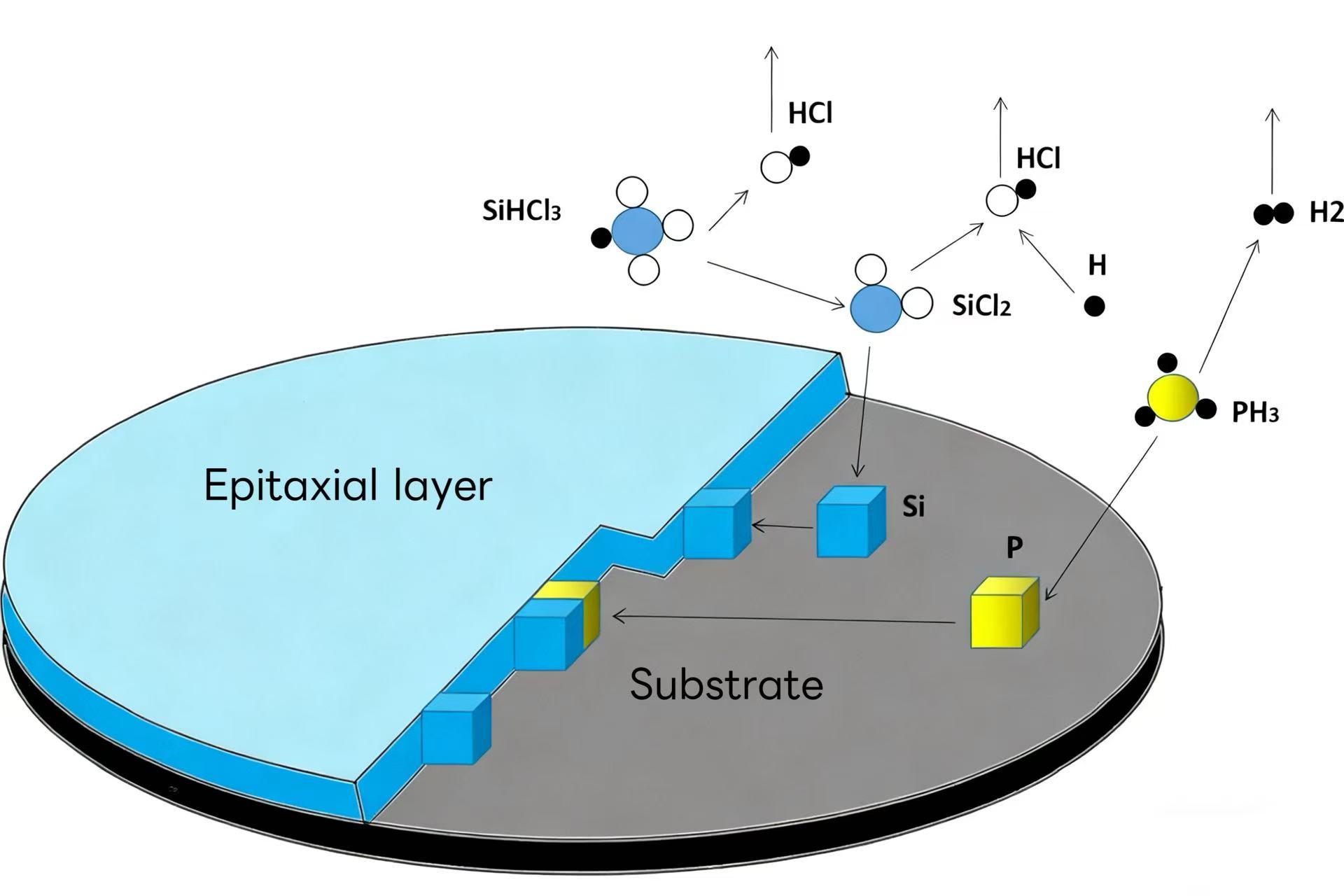

Silicon epitaxy generally uses a vapor phase epitaxy furnace. Its principle is that the decomposition of silicon source (such as silane, dichlorosilane, trichlorosilane, and silicon tetrachloride reacts with hydrogen to generate silicon. During growth, doping gases like PH₃ and B₂H₆ can be introduced simultaneously. The doping concentration is precisely controlled by the gas partial pressure to form an epitaxial layer with a specific resistivity.

The Advantages of Silicon Epitaxy for Devices

1.Lower series resistance, simplify isolation techniques, and reduce the silicon controlled rectifier effect in CMOS.

2.High (low) resistivity epitaxial layers can be epitaxially grown on low (high) resistivity substrates;

3.An N(P) type epitaxial layer can be grown on a P(N) type substrate to directly form a PN junction, eliminating the compensation problem that occurs when fabricating a PN junction on a single crystal substrate using the diffusion method.

4.Combined with masking technology, selective epitaxial growth can be performed in designated areas, creating conditions for the fabrication of integrated circuits and devices with special structures.

5.During the epitaxial growth process, the type and concentration of doping can be adjusted as needed; the change in concentration can be either abrupt or gradual.

6.The type and concentration of dopants can be adjusted as needed during the epitaxial growth process. The concentration change can be abrupt or gradual.

Semicorex provides Si epitaxial components required for for semiconductor equipment. If you have any inquiries or need additional details, please don't hesitate to get in touch with us.

Contact phone # +86-13567891907

Email: sales@semicorex.com